Focuz

Your Solution to Outsource Manufacturing

Focuz Manufacturing Co., Ltd.

contact

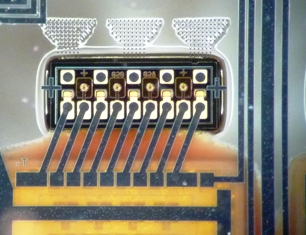

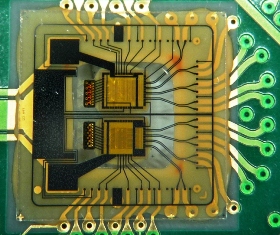

Hybrid & Laser Packaging

Focuz has extensive experience in packaging of hybrid electronic and laser for various applications: optical telecom & datacom, biomedical & healthcare, advanced consumer electronic, and industrial & metrology. The package types range from TO-Can to Box-type or Butterfly package.

Our key process capabilities are:

Die Attachment

- Eutectic with wide range of solder alloys

- Thermocompression, thermosonic, and ultrasonic processes

- Adhesive & UV curing

- Better than 1 um post-bonding accuracy

- Die shear test per MIL-STD-883

Wire Bonding

- Ball bond and stud bump with gold and copper wires

- Wedge bond with gold and aluminum wires

- Ribbon bond

- Wire pull test per MIL-STD-883

Optics Alignment & Attachment

- Submicron precision alignment

- Active/Passive

- Automated/semi-auto/manual

- Attachment processes include

- Laser welding

- Laser soldering

- Glass Soldering

- Soldering

- Adhesives

- Mechanical fastening

Hermetic Sealing

- Sealing processes include

- Projection welding

- Resistance seam welding

- Laser welding

- Glass sealing

- Soldering

- Leak test per MIL-STD-883E

Burn-In & Functional Testing

- Optical/Electrical, Digital/Analog

- Test parameters are BERs, Eye diagram, IL, BR, spectrum, wavelength, ER, etc.

Others

- Wafer dicing

- Plasma cleaning

Copyright 2018. All rights reserved.

Focuz Manufacturing Co., Ltd.

contact